JIC fittings are a type of fitting used to connect tubing in different sizes. They can be used in a wide range of applications, such as fuel, diagnostics, and fluid power systems. The body, sleeve, and nut of a fitting are precision machined components, designed to be compatible with one another.

Usually, the sleeve of the fitting is held between the main body nose and the tube. This enables the flow of fluid through the tube without losing volume. If the body of the fitting is not sleeved, it is usually used as a hose adapter.

Depending on the application, the fitting can be manufactured from a variety of materials. For example, forged brass and carbon steel are two common material types for JIC threads.

JIC fittings are based on the SAE J514 standard. However, because of differences in the standards, AN flare fittings are not interchangeable with JIC fittings.

A JIC flare nut consists of a 37 degree flare seating surface. These seats are designed to spread the compressive forces evenly across the tube.

To attach the flared nut to the flared tube, the tube must be aligned properly. If the flares are not square, they can cause the nut to collide with the nose of the fitting, resulting in leakage.

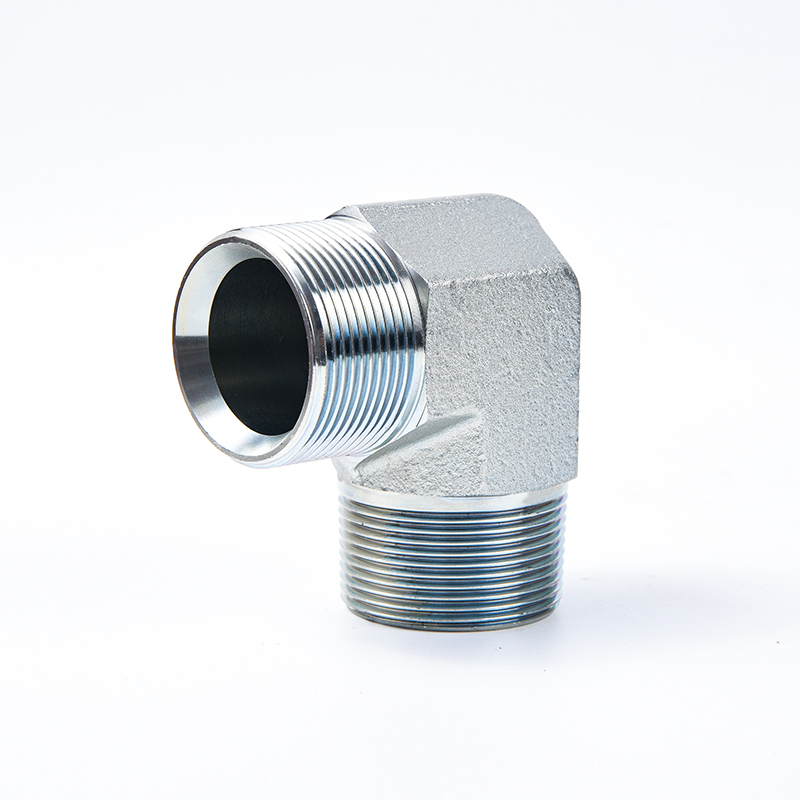

Flared fittings are available in a variety of configurations, but they are most commonly used for hydraulic and air conditioning applications. Hydraulic hoses typically use 37-1/2deg flare connections.

EN

EN  中文简体

中文简体